Many manufacturing industries are facing problems with the dust in the factory, and this problem is not just a little dust; it is a cause of safety, well-being, and environmental problems. Dust and fumes lead to many harmful issues and inhaling problems for the workers. Increasing urbanization and automation are the causes of dust and fumes. And rapidly growing health diseases in the human body.

In this blog, we will discuss advanced strategies for dust, fume, and odor control with industrial fans.

How can you clean the air with specialized fans and ventilation systems from dangerous spaces?

Keeping fresh air and reducing the harmful gases from the factories is the purpose of the ventilation system. It helps to maintain and remove all the hazardous gases and components in the air. You know that in the market, there are various ventilation options available; choosing the best ventilation can be problematic. Ventilation exhaust fans improve the indoor air quality and reduce harmful gases such as CO2 etc. The country's humidity levels in industry are beneficial for health and reduce air pollution, so that all employees can easily breathe and not face any health issues.

Ventilation fans: types of systems for factories and industries, reducing harmful gases.

For factory ventilation fans, quality is a major part of the industrial environment. All the factories and manufacturing units work with many harmful chemicals and gases that are hazardous to human health and the environment. A ventilation system is necessary in the factory for safety and to improve efficiency.

Exhaust ventilation system

The main purpose is to breathe out the hot air from the factory. These

exhaust fans throw out the dust, fumes, and odor. And this is the best idea for chemical industries and paint factories.

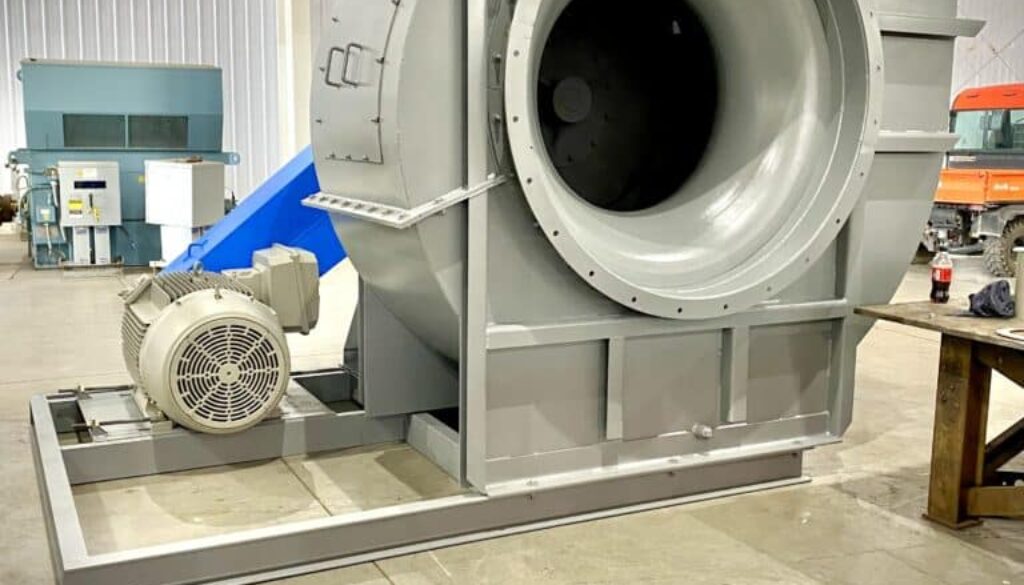

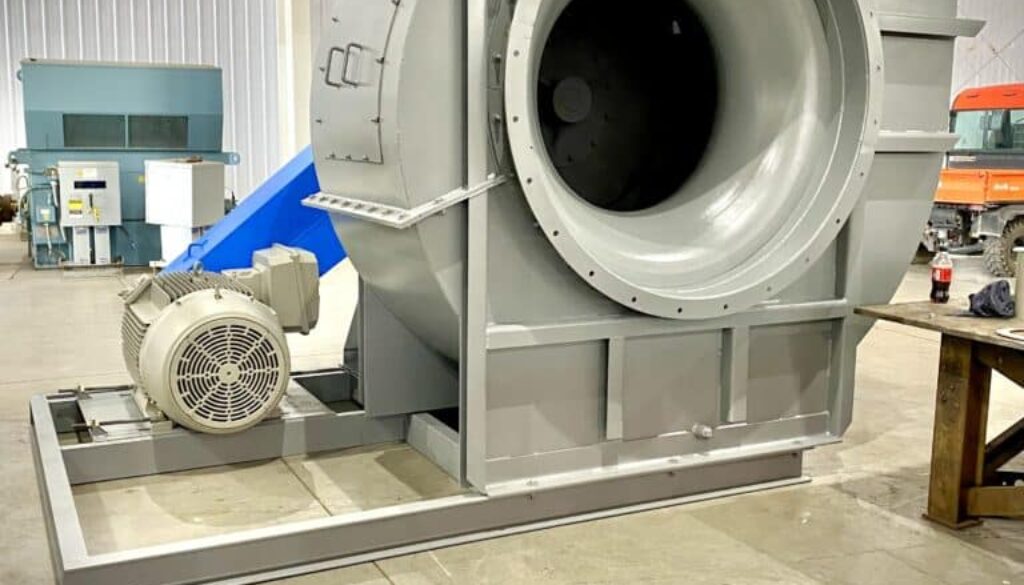

Centrifugal exhaust fans

They collect all the heat of the factory and centralize it in the middle and throw it away at a 90-degree angle. It is known for its unique name, roof exhaust. It is very durable and runs for many years.

Mixed flow fans

These fans are multi-talented because they work as a mixture of centrifugal and axial exhaust fans that regulate the airflow and provide smooth breathing to the employees.

Axial exhaust fans

It is looks like a propeller fans and it throws out the air in stragightforward and easy to setup of this fan.

Wall exhaust fans

They continuously pull the air from the room; they are best for warehouses and reduce continuous heat from the factory.

Let's understand the types of industrial ventilation systems:

- Air supply system: The air supply system is known for its special design. This fan reduces the large amount of hot air, increases the quality of air, and controls humidity. It supplies fresh air into the factories and automatically reduces the hot air.

- Balanced ventilation systems: This ventilation system controls overall indoor pollution and passes the air, and improves the quality of indoor air. These exhaust fans' mechanism some fans and filters add in this exhaust fan.

- Dilution ventilation system: This ventilation system needs to be set up for large spaces like factories and warehouses. It is cost-effective and reduces hot air so you can easily install it.

- Local exhaust ventilation: it releases the harmful gases from the factory and is most powerful in a toxic environment. It contains capture points like a duct cooler and a filter. It is mostly used in laboratories and welding factories.

Deep diving into the air contaminants

Air contaminants are those unwanted hazardous presences in the air that have a dangerous impact on humans’ health, equipment, and environment, mostly in manufacturing units and chemical plants. In the air, particles of harmful gases or fumes are made by man, and this impact results in the manufacturing process, equipment, and employees of the factories.

- Dust particles are in the air because of pollution.

- Harmful gases in the air because of chemical factories, which produce many types of gases like CO and SO₂

- Fumes are very solid particles, and they are generated from the hot metals.

- Their long-term exposure can be the cause of health diseases and skin cancer.

- Some gases are explosive, so it is necessary to have exhaust fans in the factories.

What makes Bigvent fans the ultimate choice against dust, fumes, and odors?

When the discussion begins on industrial air quality, the first name is Bigvent fans. Because Bigvent fans have delivered their services for 9 years. It has built its strong existence in the industrial air cooling market. Their consumer reviews attest to their product stability and excellent performance. Their excellent products give you the coolest environment in your factory and increase productivity and stability.

FAQ: Advanced Strategies for Dust, Fume, and Odor Control with Industrial Fans

Question 1. How can I maintain industrial fans?

Answer: You need to regularly analyze your fans and make an inspection after the season, clean their blades and water tank, and grease all over the motor mechanism.

Question 2. Why is dust control essential for industries?

Answer: Dust is very harmful to your employees, machinery, and productivity. Because dust is the cause of skin irritation, itching, and many chronic diseases like skin cancer, when your employees face all these problems, your productivity also decreases.

Question 3. Local exhaust system: what is it?

Answer: The local exhaust system is the exhaust that is mostly used in welding factories because it captures all the dust and pollutants before they spread and removes them.

Question 4. What are the industrial fans' specifications?

Answer: The industrial fans regulate the airflow capacity, pressure, horsepower, and noise level.