Demand For Industrial Fans?

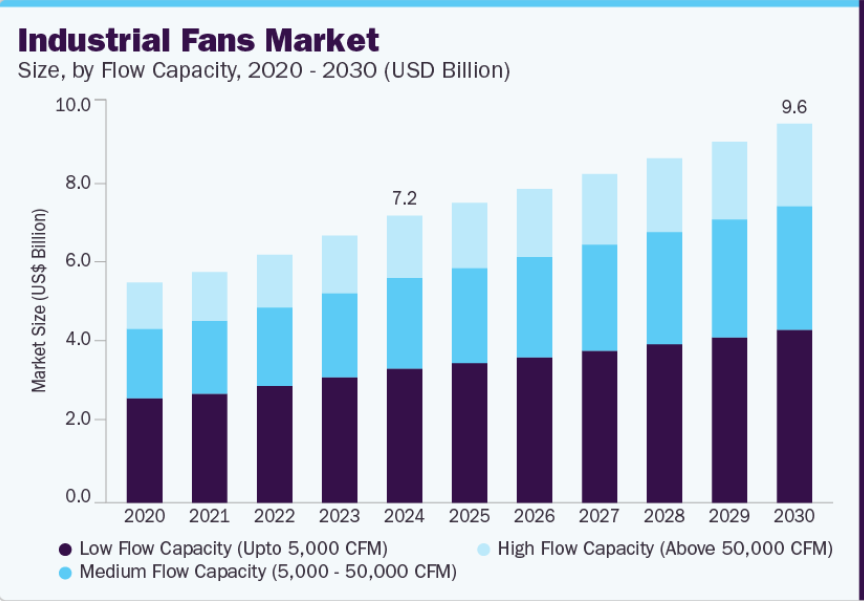

As per the recent study by Grand View Research, the global industrial fans market size is valued at USD 7,240.2 million in 2024, and it is estimated to grow at a CAGR of 4.8% from 2025 to 2030. In 2024, the Asia-Pacific region accounted for the largest revenue share at 41.3%.Indian Fans Market: The Indian HVLS fans market is valued at 108.5 INR Crores in 2024, and it is anticipated to reach 247 INR Crores by 2031, with a growing CAGR of 12.9% during the forecast period 2025-2031. According to Precision Business Insights.

How Does Industrial Machinery Overheating Occur In Industrial Operations?

The industrial machinery overheats when the heat is generated from the continuous operations of heavy-duty machinery operating around the clock. This leads to a rise in the higher temperatures and critical temperatures. Mostly in the machine industries, the machines are operating for long hours, which results in the electric motor, bearings, nd the electric components not having sufficient time to cool down. It not only affects your productivity it also affects your pocket because the asset lifespan decreases, and enhances the chances of unexpected breakdowns.Key Reasons for Machinery Overheating:

- Continuous friction and overcapacity operations

- Insufficient airflow that enhances machinery heating & disturbs workers' comfort

- Heavy friction generated by poor, degraded lubrication

- Loose electric wiring, voltage faults, and electrical faults

- Dust and debris stirring machinery

- Insufficient, poorly maintained cooling system

How Do Industrial Fans Help To Reduce Machine Overheating?

The industrial fans play a crucial role in maintaining sufficient airflow in every large industrial environment. Industrial fans help protect huge machinery from overheating and remove excess heat stress from the critical components of the machine. When the airflow is not maintained in the large industrial environments. So the machines generate lots of heat by working with friction, electrical load, and continuous operations without stopping. The best ventilation layout designs for large industrial sheds, factories, and manufacturing units decrease the risk of costly downtime.- Industrial fans enhance sufficient airflow for reducing accumulated heat and the equipment.

- Provide effective Heat dissipation around the critical machine components

- Reducing the hot air pockets in poorly ventilated areas.

- Support industrial operating temperatures during long production cycles.

- Reduce the burden from motor, bearing, and electrical components

- Enhance machinery lifespan by providing effective cooling

What Are The Best Industrial Fans Types For Large Industries?

The industrial fans are designed to deliver different configurations for managing heat efficiency across large industrial layouts. Choosing the right industrial fan means ensuring effective airflow, temperature control, and long-term machine operation. Below, we mentioned the best fan types that are used for machine cooling, enhancing workers’ comfort, and the best purpose of heat management.Axial Fans

The axial fans are the most ideal for applications that require high airflow at low pressure. These fans are specially used for machine cooling, motor cooling, and the heat exchanger system. Its compact design works efficiently and makes it suitable for continuous cooling of confined spaces.Features Of Axial Fans

- High airflow capacity

- Working with low-pressure operations

- Compact space-saving designs

- Energy efficient

- Noise control options

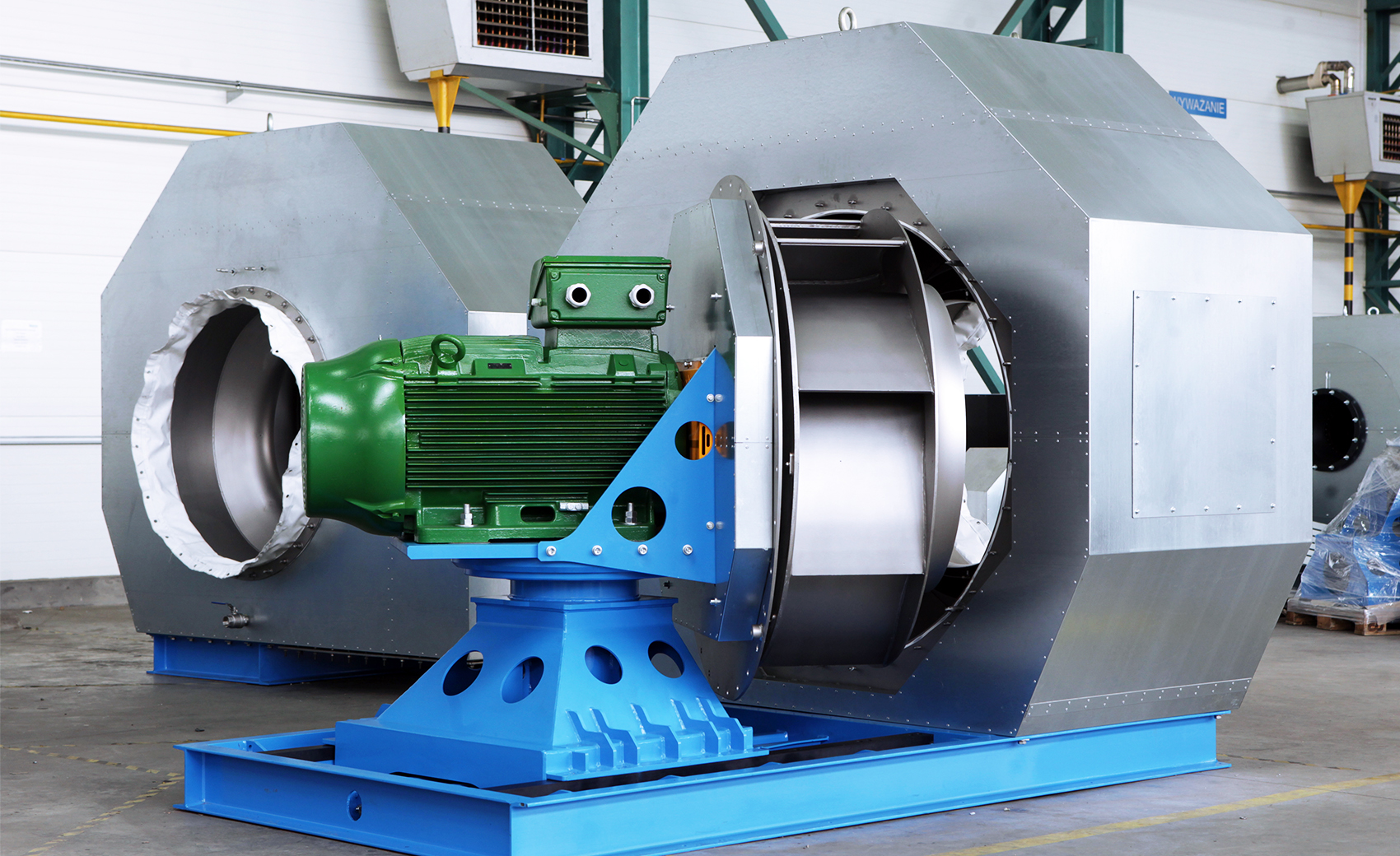

Centrifugal Fans

Centrifugal fans are established in the center of the industry that work by drawing air into the center or providing airflow at a 90-degree angle. This fan is the best for every industrial environment, because it provides effective cooling and protects your industry from dust.Key Features:

- Efficient air direction

- Excellent dust particle handling

- Durable & durable design

- Wider range of blade designs

- Energy-efficient solution for industry

- Wider industrial applications

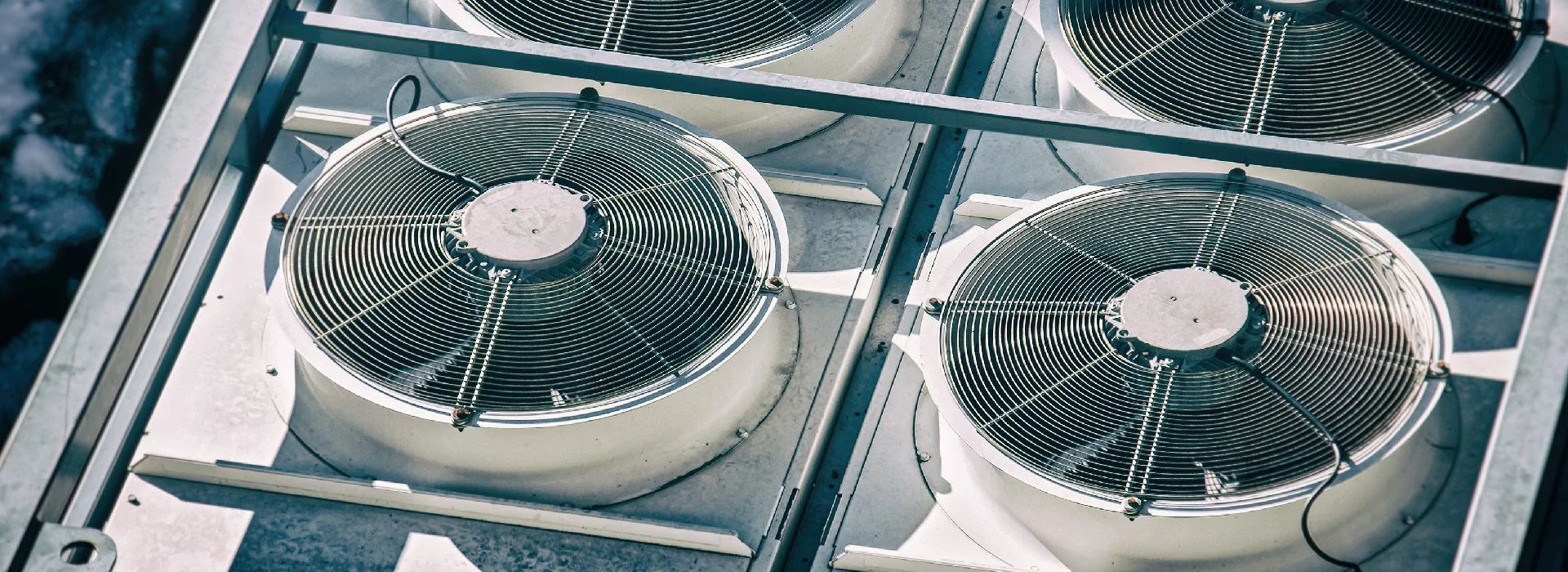

Exhaust Fans

Industrial large exhaust fans are designed to remove humidity, moisture from the large industrial areas. It absorbs warm air and provides effective cool air. Exhaust fans are essential for reducing heat, moisture, and harmful fumes from the air, which makes a heavy impact on machinery.- Reduce hot air from the industrial environment

- Improve indoor air quality with ventilation

- Remove heat and humidity from large industries

- Energy-efficient & cost-effective operation

- Supports continuous airflow

- Less maintenance and long life service

- Suitable for commercial, industrial, and residential use

HVLS Fans

High volume, large speed fans are working with large diameter fans that are especially designed for providing a massive amount of air in every industrial environment. These HVLS fans operate slowly and provide large airflow across the industrial spaces, and maintain a consistent, comfortable environment for workers and machinery. The industrial HVLS fans are suitable for factories, warehouses, manufacturing units, and the automotive industries.- Circulates a large volume of air at a rotational speed

- Provide accurate airflow access to the large industrial spaces

- Increase thermal comfort and temperature consistency

- Reduce heat stress from workers and machinery

- Quiet operations that do not affect production

- Suitable for large industrial environments