HVLS Fans for Industries

Buy HVLS Fans for Industries Online

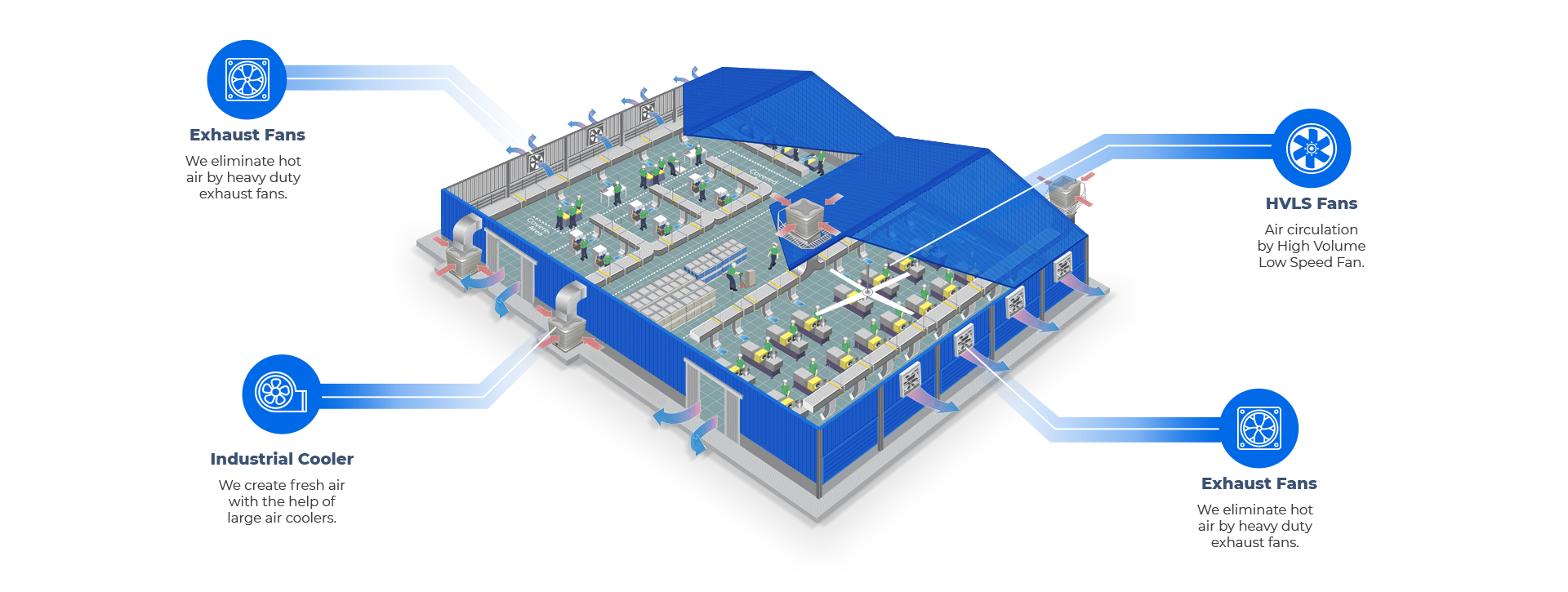

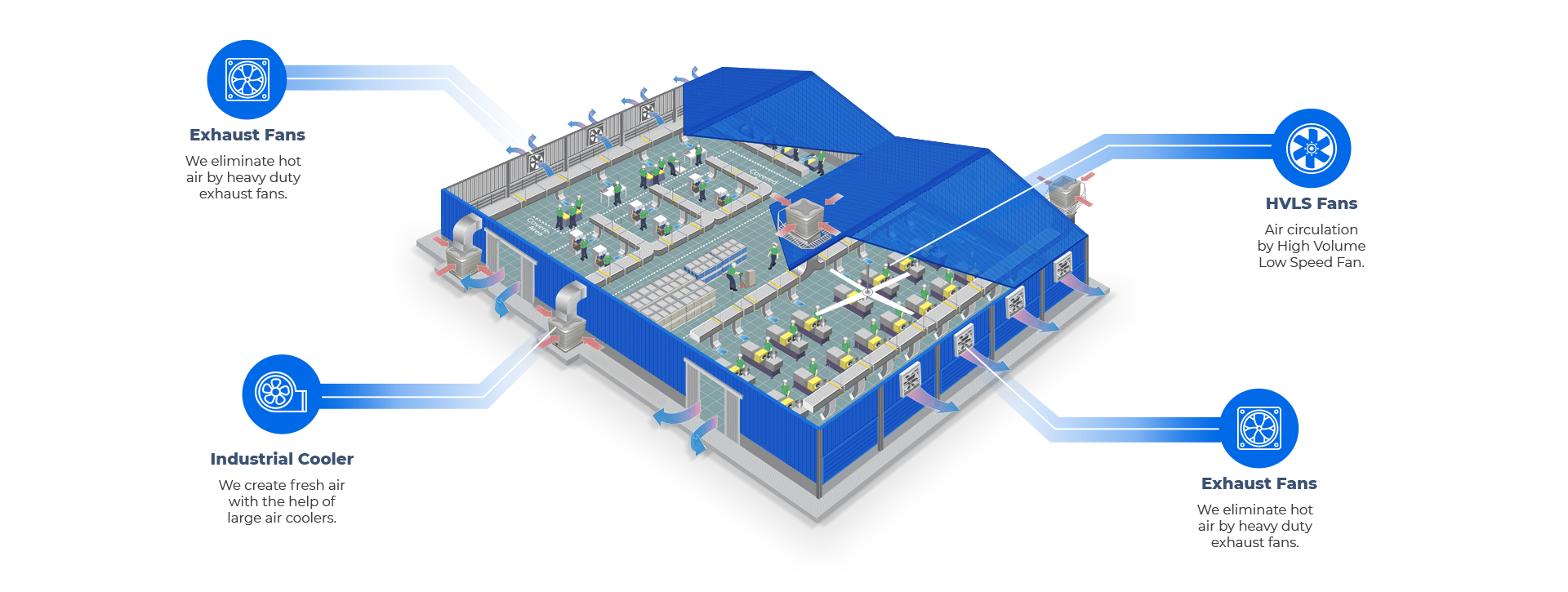

Nowadays, businesses must prioritize power efficiency and worker amenities. Standard HVAC systems may not cool big & open areas. HVLS fans present a bearable and efficient solution to improve air circulation, reduce energy consumption, and improve overall ease and productivity in industrial spaces.

What is the HVLS Fan?

HVLS fans are big fans that drive slowly but form a strong airflow, protecting a vast area. Unlike orthodox ceiling fans, HVLS fans rely on natural airflow to cool the area. Rather, they form air movement, conducting a wind chill impact that lowers sensed temperatures and improves air circulation.

Benefits of HVLS Fans in Industries -

Power Efficiency - HVLS fans consume significantly less energy compared to traditional HVAC systems, making them a cost-effective solution.

Enhanced Air Circulation - By forming a strong airflow, HVLS fans can spread heat and humidity throughout the area, providing a more relaxed atmosphere.

Reduced Power Expenditures - HVLS fans can help decrease energy consumption by letting you lessen the thermostat set, resulting in notable savings on your power bills.

Enhanced Indoor Air Quality - HVLS fans can help enhance indoor air quality by decreasing the engagement of pollutants and allergens by improving air circulation.

Enhanced Employee Comfort - A relaxed work atmosphere can increase worker morale, productivity, and general well-being. HVLS fans can help form a more enjoyable environment for your workers.

Versatility - HVLS fans can be used in a broad range of commercial and industrial environments, including warehouses, factories, retail areas, and farming structures.

When choosing an HVLS fan for industries, there are several aspects to consider -

Mounting Height

HVLS fans should be lodged at the lowest height of 10 feet beyond the ground, with an excellent range between 20 and 30 feet.

Size -

HVLS fans are known in different sizes, varying from 6 to 24 feet in diameter. The size you select should lean on the place you wish to cover and the roof height.

Acquittance -

Make sure there is sufficient space below the fan for big tools like forklifts, shelving, man lifts, and frames.

Light Strobing-

To control light strobing, improve the vertical space or flat separation between the fan edges and the light source.

Varying Frequency Movement-

The VFD controls the fan's speed and implementation. Use the factory wiring graph to connect the VFD to the engine.

Controller -

Consider your needs when selecting a control for your HVLS fan system. If you want to contain the fan system into an existing BMS system, you might want to select the iFan Series.

Wrapping Up!

In conclusion, HVLS fans present an affordable and power-efficient solution for enhancing air circulation and ease in industrial areas. Evaluate aspects like height, size, clearance, light strobing, variable frequency motion, and control when selecting an HVLS fan for your typical industrial requirements.

INDUSTRIES WE SERVE

Airport

Auditorium

Automobile

Bus Station

Commercial

Convention Halls

Industries

Libraries

Railway Station

OUR SOLUTIONS

OUR RELATIONSHIPS